What is ISO 22000:2018?

ISO 22000:2018 is an international standard that outlines the requirements for a food safety management system. It is intended to ensure that food products are safe for human consumption by addressing all stages of the food supply chain, from the initial production and processing of raw materials, to transportation, storage, and distribution. The standard is based on the principles of Hazard Analysis and Critical Control Points (HACCP) and emphasizes the importance of ongoing management and review of the food safety system.

Organizations that implement and maintain FSMS in accordance with ISO 22000:2018 can be certified by an accredited third-party certifying body, which demonstrates to customers, regulators, and other stakeholders that the organization's food safety management system meets international standards.

Benefits of ISO 22000 for food producers

There are many benefits of food safety standard for food producers, including:

Improved food safety:

ISO 22000 helps to improve the overall safety of the food produced by requiring hazard analysis and critical control points (HACCP), and other food safety controls. This can help to reduce the risk of food-borne illnesses and other food safety issues.

Increased quality:

FSMS helps to improve the overall quality of food produced by requiring a comprehensive food safety management system standard. This can lead to increased consumer confidence and satisfaction in the food produced by a company.

Standardization:

This ISO Standard helps to standardize the food production process, making it easier for food producers within the food chain to comply with local and international regulations, and to improve the overall efficiency of production process.

Increased market access:

Many countries and retailers around the world require or prefer suppliers to have ISO 22000:2018 certification, so having this certification can help food producers to access new markets and customers.

Cost savings:

Implementing the standard ISO 22000 can help food producers, any organization to identify and eliminate inefficiencies in their food production process, which can lead to cost savings and is applicable to all organization.

Continuous improvement:

ISO 22000 requires regular review and improvement of the food chain regardless of size of producers to stay ahead of emerging food safety issues and improve their overall performance.

Overall, the standard ISO 22000 is an important tool for food producers who are looking to improve the safety, quality and the efficiency of their food production process within the food chain. It can help to increase consumer confidence, open new markets and save costs in the long run & minimize the food safety hazards.

Is ISO 22000 certification right for me?

Determining whether ISO 22000 certification is right for

your organization depends on various factors and considerations. Here are some

points to help you assess the suitability of ISO 22000 certification for your

specific circumstances:

- Industry

and Sector: ISO 22000 is specifically designed for organizations

operating in the food industry. If your organization is involved in any

aspect of the food supply chain, such as primary production,

manufacturing, processing, distribution, or food service, ISO 22000

certification can be highly relevant and beneficial.

- Regulatory

Compliance: ISO 22000 provides a structured approach to complying with

food safety regulations and standards. If your organization operates in a

jurisdiction with specific food safety regulations or if your customers

require compliance with recognized food safety standards, ISO 22000

certification can help you meet these requirements.

- Customer

Expectations: ISO 22000 certification can be an asset when dealing

with customers who prioritize food safety and require assurance that your

organization has implemented effective food safety management systems.

Certification can enhance your credibility and differentiate you from

competitors, demonstrating your commitment to delivering safe food

products.

- Supply

Chain Requirements: ISO 22000 certification can be advantageous if

your organization is part of a complex food supply chain. Certification

can provide assurance to your partners and stakeholders that you have

implemented robust food safety measures, helping to build trust, and

facilitating business relationships.

- Internal

Benefits: ISO 22000 certification goes beyond regulatory and customer

requirements. It can bring internal benefits, such as improved operational

efficiency, risk management, and quality control. Certification can help

you establish standardized processes, enhance communication, and foster a

culture of food safety within your organization.

- Resource

Commitment: It's important to consider the resources required for

implementing and maintaining an ISO 22000-compliant Food Safety Management

System. This includes personnel, training, documentation, infrastructure,

and ongoing audit and certification costs. Assess whether your

organization has the necessary resources and commitment to allocate to the

certification process.

It is advisable to conduct a thorough assessment of your

organization's needs, goals, and capabilities before pursuing ISO 22000

certification. Consider consulting with a qualified professional or

certification body, Quality Management System Nepal P. Ltd., to gain a better

understanding of the specific benefits, requirements, and potential challenges

associated with ISO 22000 certification in your context.

What are ISO 22000 standards?

ISO 22000 is an internationally recognized standard that

specifies the requirements for a Food Safety Management System (FSMS). The

standard provides a comprehensive framework for organizations in the food

industry to manage food safety and ensure the delivery of safe products to

consumers. Here are the key elements and standards covered by ISO 22000:

- Food

Safety Management System (FSMS):

- ISO

22000 outlines the requirements for establishing, implementing,

maintaining, and continually improving an FSMS within an organization.

- It

provides a systematic approach to managing food safety hazards, including

identifying and assessing hazards, determining control measures, and

monitoring their effectiveness.

- Hazard

Analysis and Critical Control Points (HACCP):

- ISO

22000 incorporates the principles of Hazard Analysis and Critical Control

Points (HACCP) as a fundamental part of the FSMS.

- It

requires organizations to conduct a thorough hazard analysis, identify

critical control points (CCPs), establish critical limits, and implement

monitoring and corrective actions to control food safety hazards.

- Prerequisite

Programs (PRPs):

- ISO

22000 mandates the implementation of prerequisite programs (PRPs) to

establish a foundation for food safety.

- PRPs

include general hygiene practices, sanitation procedures, pest control,

personnel hygiene, facility maintenance, and other basic conditions

necessary to maintain a hygienic environment throughout the food chain.

- Communication

and Documentation:

- ISO

22000 emphasizes the importance of effective communication and

documentation within the FSMS.

- It

requires organizations to establish clear communication channels, both

internally and externally, to ensure the flow of relevant information

related to food safety.

- Documentation

requirements include developing and maintaining documented procedures,

work instructions, records, and other necessary documentation to

demonstrate compliance with the standard.

- Management

Responsibility and Commitment:

- ISO

22000 places a strong emphasis on leadership commitment and management

responsibility for food safety.

- Top

management is required to establish a food safety policy, set objectives,

provide resources, and promote a culture of food safety throughout the

organization.

- Performance

Evaluation and Improvement:

- ISO

22000 emphasizes the need for organizations to monitor, measure, analyze,

and evaluate the performance of their FSMS.

- Internal

audits, management reviews, and continual improvement processes are

integral parts of ISO 22000 to identify areas for improvement, take

corrective actions, and enhance the effectiveness of the FSMS.

What are the four major elements of ISO 22000?

The four major elements FSMS include:

Management commitment:

This element requires that food producers in supply chain have a strong commitment to food safety, and that they establish FSMS standards that is designed to meet the requirements of food safety from farm to fork and minimize food safety hazards.

Hazard analysis and critical control points (HACCP):

This element requires that food producers conduct a thorough analysis of hazards that may be present in their food production process, and that they implement controls to prevent these hazards from occurring.

Prerequisite programs:

This element requires that food producers have in place certain programs and procedures that are designed to help prevent food safety issues from occurring.

Continuous improvement:

This element requires that food producers regularly review and improve their food safety management and ensure that it remains effective and meets the requirements for ISO 22000.

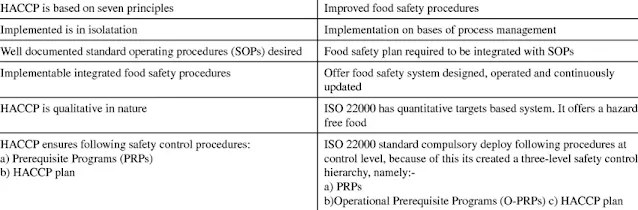

What is difference between HACCP and ISO 22000?

HACCP (Hazard Analysis and Critical Control Points) and ISO 22000 (Food Safety Management System) are both frameworks designed to ensure food safety.

However, there are several key differences between the two:

1. Scope:

• HACCP: HACCP is a risk-based system that focuses specifically on identifying and controlling hazards that are significant to food safety. It is primarily applied at the operational level and is often implemented within specific processes or facilities.

• ISO 22000: ISO 22000 provides a broader framework for managing food safety throughout the entire food supply chain. It encompasses a comprehensive Food Safety Management System (FSMS) that includes organizational structure, planning, control measures, and continual improvement.

2. Approach:

• HACCP: HACCP follows a systematic approach of hazard analysis and control based on seven principles. It focuses on identifying critical control points (CCPs) where hazards need to be controlled to ensure food safety.

• ISO 22000: ISO 22000 takes a more holistic approach to food safety management. It combines elements of HACCP with additional requirements such as prerequisite programs, management system principles, and performance evaluation. ISO 22000 requires a broader perspective on food safety hazards, including biological, chemical, and physical hazards.

3. Certification:

• HACCP: HACCP itself is not a certifiable standard but rather a system that can be implemented and verified through internal or external audits.

• ISO 22000: ISO 22000 is an internationally recognized standard that can be certified by accredited certification bodies. Organizations can undergo a formal certification process to demonstrate compliance with the standard's requirements.

4. Integration:

• HACCP: HACCP is often integrated into broader food safety management systems or quality management systems within organizations.

• ISO 22000: ISO 22000 can be integrated more easily with other management system standards, such as ISO 9001 (Quality Management) or ISO 14001 (Environmental Management), due to its alignment with the Annex SL framework.

5. Applicability:

• HACCP: HACCP is commonly applied in sectors directly involved in food production, processing, and handling, such as manufacturing facilities, restaurants, and food service providers.

• ISO 22000: ISO 22000 is applicable to organizations of all sizes and sectors within the food supply chain, including primary producers, manufacturers, processors, distributors, and service providers.

While HACCP is a specific risk-based system primarily focused on identifying and controlling hazards at critical points, ISO 22000 provides a broader framework for managing food safety throughout the entire supply chain. ISO 22000 incorporates elements of HACCP and additional requirements, allowing for a more comprehensive and integrated approach to food safety management.Additionally, HACCP is a food safety management system that is used as a guideline while ISO 22000 is an International standard and certification can be obtained for the compliance of the standard.

Who should use ISO 22000?

ISO 22000 is designed for organizations operating in the

food industry, including various sectors within the food supply chain. Here are

some examples of who should consider using ISO 22000:

- Food

Manufacturers: ISO 22000 is highly relevant for food manufacturing

companies that produce a wide range of food products. It helps ensure the

safety of ingredients, processing methods, packaging, and labeling,

enabling manufacturers to deliver safe products to consumers.

- Food

Processors: Organizations involved in processing food, such as canning,

baking, pasteurization, or freezing, can benefit from ISO 22000. It helps

manage potential hazards at different stages of processing and ensures

adherence to food safety standards.

- Food

Service Providers: Restaurants, cafeterias, hotels, catering companies,

and other food service establishments can implement ISO 22000 to maintain

food safety during food preparation, handling, and service. It helps

establish procedures and controls to minimize the risk of foodborne

illnesses.

- Primary

Producers: Agricultural farms, fisheries, and other primary producers can

adopt ISO 22000 to manage food safety risks associated with raw materials,

cultivation practices, harvesting, and storage. It assists in maintaining

the integrity and safety of products from the earliest stages of the food

supply chain.

- Food

Packaging and Distribution: Companies engaged in food packaging, storage,

and transportation play a crucial role in maintaining food safety. ISO

22000 can help these organizations implement best practices and controls

to ensure the safety and integrity of packaged and distributed food

products.

- Food

Retailers: Supermarkets, grocery stores, and other retail outlets that

sell food products can benefit from ISO 22000. It helps establish

procedures for proper storage, handling, and display of food items to

prevent contamination and ensure product safety.

- Food

Service Consultants and Auditors: Professionals providing food safety

consultancy and auditing services can use ISO 22000 as a framework to

assess and improve food safety practices in various organizations. It

provides a structured approach for evaluating compliance and identifying

areas for improvement.

It's important to note that ISO 22000 can be adapted to suit

organizations of all sizes, from small businesses to large enterprises. Whether

you are involved in food production, processing, distribution, or service, ISO

22000 offers a comprehensive framework for managing food safety risks and meeting

regulatory and customer requirements.

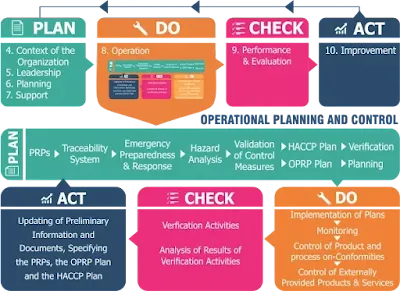

ISO 22000 requirements for Food Safety Management Systems

ISO 22000 sets out the requirements for establishing,

implementing, maintaining, and continually improving a Food Safety Management

System (FSMS). The standard consists of several clauses and sub-clauses that

organizations need to address to achieve ISO 22000 certification. Here is an

overview of the key requirements outlined in ISO 22000:

- Scope

(Clause 1): This clause defines the scope of the FSMS, including the

organization's activities, products, and services covered by the system.

- Normative

References (Clause 2): This clause lists the relevant international

standards and other documents referenced in ISO 22000.

- Terms

and Definitions (Clause 3): This clause provides definitions of specific

terms used throughout the standard to ensure a common understanding.

- Context

of the Organization (Clause 4): This clause requires organizations to

determine external and internal issues that can impact the FSMS, including

the needs and expectations of interested parties.

- Leadership

(Clause 5): This clause emphasizes the commitment and involvement of top

management in establishing the FSMS, setting food safety objectives, and

ensuring the availability of necessary resources.

- Planning

(Clause 6): This clause focuses on the establishment of food safety

objectives, development of plans to achieve them, and risk assessment

related to food safety hazards.

- Support

(Clause 7): This clause covers requirements related to resources,

competence, awareness, communication, documented information, and

emergency preparedness and response.

- Operation

(Clause 8): This clause encompasses the implementation of operational

planning and control measures to ensure effective control of food safety

hazards, including the use of PRPs and the implementation of the HACCP

system.

- Performance

Evaluation (Clause 9): This clause includes requirements for monitoring,

measuring, analysis, and evaluation of the FSMS, including internal

audits, management reviews, and the handling of nonconformities.

- Improvement

(Clause 10): This clause focuses on the need for organizations to take

corrective actions, continually improve the FSMS, and update processes

based on the results of monitoring, evaluation, and reviews.

Within each clause, there are additional sub-clauses and

specific requirements that organizations must fulfill to meet the criteria set

out by ISO 22000. These requirements provide a structured framework for

organizations to manage food safety hazards, establish control measures, and

ensure the delivery of safe food products to consumers.

ISO 9001 vs ISO 22000

Food safety management system standards requires organizations to implement FSMS that covers all aspects of the food production process, from raw materials to the finished product.

ISO 9001 and ISO 22000 are two distinct international

standards that focus on different aspects of management systems within

organizations. Here are the key differences between ISO 9001 (Quality

Management System) and ISO 22000 (Food Safety Management System):

- Scope

and Focus:

- ISO

9001: ISO 9001 is a generic standard that focuses on establishing a

quality management system to meet customer requirements, enhance customer

satisfaction, and continually improve organizational performance. It

addresses various aspects of quality management, including customer

focus, leadership, process approach, and performance evaluation.

- ISO

22000: ISO 22000 specifically addresses the requirements for a Food

Safety Management System (FSMS). It aims to ensure food safety throughout

the entire food supply chain, from primary production to final

consumption. ISO 22000 focuses on the control of food safety hazards and

the delivery of safe products to consumers.

- Industry

Applicability:

- ISO

9001: ISO 9001 is applicable to organizations of any size and sector,

regardless of their specific products or services. It is widely used

across industries and sectors as a framework for implementing a quality

management system.

- ISO

22000: ISO 22000 is specifically designed for organizations operating in

the food industry, including primary producers, manufacturers,

processors, distributors, and service providers. It addresses the unique

challenges and requirements of ensuring food safety in the food supply

chain.

- Hazard

Analysis:

- ISO

9001: ISO 9001 does not explicitly require organizations to conduct a

hazard analysis or identify specific risks related to product quality. It

focuses more on meeting customer requirements, enhancing process

efficiency, and continuous improvement.

- ISO

22000: ISO 22000 requires organizations to conduct a thorough hazard

analysis to identify, assess, and control food safety hazards throughout

the food supply chain. It emphasizes the identification and control of

biological, chemical, and physical hazards that can pose risks to food

safety.

- Certification:

- ISO

9001: ISO 9001 certification demonstrates that an organization has

implemented a quality management system in accordance with the standard's

requirements. It is widely recognized and can provide assurance to

customers and stakeholders about an organization's commitment to quality.

- ISO

22000: ISO 22000 certification indicates that an organization has

implemented a Food Safety Management System that meets the requirements

of the standard. It demonstrates a commitment to ensuring food safety and

can provide confidence to customers, regulators, and stakeholders in the

food industry.

- Integration:

- ISO

9001: ISO 9001 can be easily integrated with other management system

standards, such as ISO 14001 (Environmental Management) or ISO 45001

(Occupational Health and Safety), using the Annex SL framework. This

allows organizations to create an integrated management system that

addresses multiple aspects of their operations.

- ISO

22000: ISO 22000 can also be integrated with other management system

standards, particularly those related to quality, environmental, and

health and safety management. However, its integration is more specific

to the food industry and the unique requirements of food safety.

ISO 9001 focuses on overall quality management and customer

satisfaction across various industries, while ISO 22000 specifically addresses

food safety management in the food industry. ISO 9001 is more generic and

applicable to organizations of any size and sector, whereas ISO 22000 is

tailored to food-related businesses.

How can an organization get certified to ISO 22000?

To get certified to ISO 22000, an organization needs to establish and implement a food safety management system that meets the requirements of the standard. The organization can then undergo an external audit by an accredited certification body to assess its compliance with ISO 22000. If the organization passes the audit, it will receive ISO 22000 certification.

Is ISO 22000 certification mandatory?

What is the latest version of ISO 22000?

Frequently Asked Questions:

- What

is food safety? Food safety refers to the measures and practices taken

to ensure that food is safe to consume and free from contamination,

toxins, and harmful microorganisms that can cause illness or harm to

consumers.

- What

is food safety and why is it important? Food safety is the assurance

that the food we consume is safe and free from any potential hazards. It

is crucial to prevent foodborne illnesses, protect public health, and

maintain consumer confidence in the food supply chain.

- What

is the main purpose of food safety law? The main purpose of food

safety laws is to regulate and enforce standards, guidelines, and

practices related to the production, handling, processing, and

distribution of food to ensure public health and safety.

- Why

is food safety important? Food safety is important to safeguard public

health, prevent foodborne diseases, maintain consumer trust, comply with

legal requirements, and enhance the overall quality and integrity of the

food industry.

- What

are 5 food safety rules? The five basic food safety rules are: a) Wash

hands and surfaces often. b) Separate raw and cooked foods to avoid

cross-contamination. c) Cook food to the proper temperature. d) Store food

at the appropriate temperature. e) Use safe water and raw materials for

food preparation.

- What

do you mean by food safety? Food safety refers to the scientific

discipline and set of practices aimed at ensuring that food is safe to

eat, reducing the risk of foodborne illnesses, and maintaining the quality

and integrity of food products.

- What

is a food safety system? A food safety system is a comprehensive set

of policies, procedures, and practices designed to manage, control, and

ensure the safety and quality of food throughout the entire food supply

chain from production to consumption.

- What

is food and safety? It seems like there might be a typo in the

question. If you meant "food safety," please refer to the

previous answer.

- Can

water safety be included in food safety? Yes, water safety is an

integral part of food safety. The quality of water used in food production

and preparation can significantly impact the safety and quality of the

final food product.

- How

can we manage food safety at the commercial level? At the commercial

level, food safety can be managed through implementing good manufacturing

practices (GMP), Hazard Analysis Critical Control Point (HACCP) systems,

regular inspections, staff training, and adherence to relevant food safety

standards and regulations.

- How

can we manage food safety at home? Food safety at home can be managed

by following proper hygiene practices, using separate cutting boards for

raw and cooked foods, cooking food to the recommended temperatures,

storing perishable foods in the refrigerator, and practicing good

handwashing.

- How

can you ensure the safety of food sold? The safety of food sold can be

ensured by conducting regular quality checks, adhering to food safety

standards, maintaining proper hygiene and sanitation, implementing a HACCP

system, and staying updated with food safety regulations.

- Is the National Food Safety Policy 2076 prepared in English language? Yes the National Food Safety Policy 2076 is Prepared in English Language.

- What are the four basic principles of food safety standards? The four basic principles of food safety standards are: a) Conduct Hazard Analysis Critical Control Points (HACCP). b) Implement good manufacturing practices (GMP). c) Maintain proper hygiene and sanitation. d) Monitor and maintain food temperature during production and storage.

- What

are the four steps of food safety? The four steps of food safety are:

a) Clean: Wash hands and surfaces often. b) Separate: Keep raw and cooked

foods separate to avoid cross-contamination. c) Cook: Cook food to the

proper internal temperature to kill harmful bacteria. d) Chill:

Refrigerate perishable foods promptly to prevent bacterial growth.

- What

do you mean by food safety? This question seems to be a repeat. Please

refer to the answer provided earlier.

- What

is a vulnerable person in food safety? Vulnerable persons in food

safety are individuals who are at higher risk of developing foodborne

illnesses, such as young children, elderly people, pregnant women, and

individuals with weakened immune systems.

- What

is rubber-soled enclosed shoes clothing called in food safety? In food

safety, rubber-soled enclosed shoes are often referred to as

"non-slip" or "non-skid" shoes, which are essential

for preventing slips, trips, and falls in food handling areas.

- What

shoes clothing are called in food safety handling? The question seems

to have a typo. If you meant "What shoe clothing is required in food

safety handling?" then it would be "non-slip" or

"non-skid" shoes to maintain safety in food handling areas.

- What

to expect from a food safety course? A food safety course typically

covers topics such as proper food handling, sanitation, personal hygiene,

HACCP principles, foodborne illness prevention, and relevant regulations.

Participants can expect to gain knowledge and skills to ensure food safety

in various settings.

- Who

needs an HACCP food safety system? The Hazard Analysis Critical

Control Point (HACCP) system is essential for all food businesses,

including manufacturers, processors, distributors, and retailers. It helps

identify and control potential hazards in food production and handling.

- Why

food safety and quality management? Food safety and quality management

are crucial to ensure that food products are safe, wholesome, and meet the

expected quality standards. It helps protect consumers and build trust in

the food industry.

- Why

is food safety important in spoilage? Food safety is essential in

spoilage to prevent the growth of harmful microorganisms and toxins that

can develop in spoiled food, leading to foodborne illnesses when consumed.

- Why

is a well-designed kitchen important for food safety? A well-designed

kitchen is important for food safety as it allows for efficient flow,

segregation of different food items, proper storage, and easy cleaning. It

reduces the risk of cross-contamination and ensures safe food handling

practices.

- Why

study food safety? Studying food safety is essential for individuals

working in the food industry, as it equips them with the knowledge and skills

to maintain high standards of food safety, comply with regulations, and

protect public health.

It is important to work with a reputable ISO consultant like ISO Certification in Nepal Pvt. Ltd. that can provide cost effective expert guidance and support to your organization throughout the process of ISO 9001 implementation. We are the leading ISO System Certification body in Nepal. We will help an organization to understand requirements, implement the standard and ensure that your company is in compliance with any ISO Certification in Nepal. Besides to ISO 9001 quality management system, we also provide ISO 14001( Environmental management System certification) , ISO 22000(Food Safety Management System Certification) ISO 45001 Occupational health and safety management system , ISO 27001 Information Security Management System . ISO/IEC 17025 Testing and calibration laboratories Organic Certification in Nepal. If you have any queries as well as if you want to get your organization to be ISO Certified, please call 9840525565 to get free consultation on ISO Certification service and know which ISO standards is best for your organization.